Starting a large business is fine. Provided you have ample capital and other resources required.

However, a glimpse into the most prominent business houses of India reveals they started as small scale manufacturers and expanded over time.

It can be more difficult to find capital to start a business more often than not. Given this scenario, the best option is to start a small scale business.

Generally, such businesses require capital up to Rs. 100,000 or lesser.

Indeed, products made by small scale industries are in greater demand since product quality is often higher and prices are somewhat competitive.

25 Small Scale Manufacturing Business Ideas in India

We have already discussed 131 great business ideas with low investment here. Here we look at 25 great small scale manufacturing business ideas which can help fulfill your dreams of becoming rich.

Table of Contents

1. Manufacturing Herbal Hair Oil

Admittedly, a lot of brands of herbal hair oils that promise near miracle cures for problems such as hair loss, hair fall, and healthy hair are available in the market.

This tends to confuse consumers about which product will offer the best results. There are several traditional formulae for herbal hair oils which seem to be overlooked by large manufacturers.

You can enter this business if you possess any such traditional recipe that prevents or reduces hair loss and greying.

2. Papad & Sago Fritters

Papad and sago (sabudana) fritters are in demand all year round. Preparing them is very simple. It does not require a lot of manpower.

All you require to setup these manufacturing businesses are proper recipes and basic equipment that includes a gas stove, utensils, and plastic sheets for drying.

And of course, the basic ingredients that go into this foodstuff include flour, sago, and spices. You might also need food-grade plastic wrappers and a sealing machine.

These are available at reasonably low prices in the market. Papads and sago fritters made at home or by small scale manufacturers are readily bought by stores or cooperatives that sell them at a premium.

3. Manufacturing Exotic soaps

India is a land of exotic herbs and spices that possess medicinal qualities. Lots of these herbs and spices have beneficial effects when applied to the skin.

Further, Indians, by nature, lay heavy emphasis on bathing and freshness every morning.

All you need is a little study into the beneficial effects of certain herbs and spices on the skin and blended with the simple process of making soap.

Making exotic bathing soaps can help you enter the small scale manufacturing business that promises rich returns.

4. Manufacturing Handmade chocolates

You and I love chocolates, and so does almost everyone. Manufacturing chocolates is pretty easy. Moreover, they have a ready market since people always wish to try newer variants and exotic flavors.

You can let your culinary imagination run wild and make chocolates with any spice or fruit flavor. Chocolates also make ideal gifts during the festive season and special occasions.

You can take orders for unique varieties as well as sell regular ones through cake and pastry shops. Assuredly, there are several pastry shops that buy handmade chocolates from small scale industries.

5. Manufacturing Cookies and biscuits

Small scale manufacturing business of cookies and biscuits is exceptionally lucrative. Understandably, people look for newer tastes and varieties than those offered by large companies.

Furthermore, several smaller manufacturers and bakeries no longer produce cookies and biscuits since due to their inability to cope with stiff competition from giant companies.

Hence, there exists a vacuum in the market for cookies and biscuits made with traditional recipes that offer a taste of yesteryears.

Hence, small scale manufacturing of traditional cookies and biscuits is something you may consider to open a business.

6. Cottage butter, paneer and ghee

Nowadays, we are all accustomed to salted butter manufactured by large companies. Of course, a few varieties of unsalted butter are also available.

Despite this, there are no manufacturers of cottage butter, as it is called. Cottage butter can be described as that derived from churning buttermilk. It has immense health benefits.

Furthermore, Indians are large consumers of paneer- or milk casein, derived by splitting milk. Traditional, homemade ghee or clarified butter, as it is called abroad, also has a significant market in India.

With milk from cow and buffalo in abundant supply, a small scale manufacturing business to produce cottage butter, paneer, and ghee is sure to succeed.

7. Manufacturing Incense sticks/ Agarbatti

Over decades, the state of Karnataka, especially the city of Bengaluru, held sway over the incense sticks or agarbatti manufacture in India. Primarily, this was due to the easier availability of raw materials in that region.

Nowadays, with superior transport facilities leading to more accessible access to raw material, agarbatti manufacturing business idea is rapidly spreading to other parts of India.

The agarbatti market in India is estimated at a whopping Rs.3,500 crore annually and growing. Indian-made agarbattis are also making rapid inroads into foreign countries.

Agarbatti manufacturing is one of the small scale manufacturing businesses that show promise of exponential growth over the coming years.

8. Candles & wax products manufacturing

With power failures rampant in several parts of India, candles are in great demand. Understandably, there is a massive market for candles of all shapes and sizes.

Nowadays, one can buy small candles used on birthday cakes to jumbo-sized ones used for providing light during power outages. Candles are also used for religious ceremonies and rituals.

Additionally, a huge market for other wax products for offering at churches and other religious shrines or for decorative purposes also exists.

Making candles and wax products is fairly easy and has a ready market across the country. This makes candle and wax products making a great small scale industry idea.

9. Candy and hard-boiled sugar confectionery

Interestingly, large manufacturers seem to have relegated India's candy and hard-boiled sugar confectionery market to the backseat.

Of course, there are quite a few large players in the market, but small scale manufacturers seem to dominate this fairly unorganized market.

Machinery to make candy and hard-boiled sugar confectionery is readily available and can be easily set up at any minor premise. Furthermore, essentials from manufacturers are readily available anywhere.

Moreover, there exists a large market for such candy and confectiogredients that include sugar, glucose syrup, approved food colors, and flavors from reputed nery on the Indian Railway network, where stalls at stations sell such inexpensive products to travelers.

10. Soda & flavored drinks

A great example of small scale manufacturing business of soda of all types- plain and flavored can be seen in the state of Goa.

For just Rs.5, you can buy a 300ml glass bottle of plain soda, while orange, lemon, strawberry, and other flavored variants cost Rs.7 each.

In comparison, plain soda from large manufacturers costs Rs.10 and upwards, while flavored soft drinks are priced around Rs.15 to Rs.20 each.

Interestingly, there are over two dozen small scale soda manufacturers in Goa but each of them has a fair share of the business. This is evident from the fact they have been in business for decades.

Furthermore, they are licensed manufacturers. Admittedly, there are large players in the market, but the Goa example aptly reveals there is scope for small scale manufacturing too.

11. Fruit pulp manufacturing

Shockingly, millions of rupees worth of high-quality fruits are wasted in India annually. Primarily, this wastage occurs due to the absence of an advanced cold chain logistic system.

Sufficient refrigerated trucks and warehouses are not available to store surplus produce. You can benefit from this malady by opening a small scale manufacturing business of producing fruit pulp.

High-quality fruit pulp is in great demand among large scale ice-cream manufacturers, sweet makers, restaurants, and star-rated hotels as well as individual customers.

The demand for the pulp of seasonal fruits such as mango is said to be relatively high, especially from reputed ice-cream manufacturers and Indian sweet makers.

12. Dehydrated, frozen vegetables

As explained earlier, India is known to waste large quantities of fresh produce. This also holds good for vegetables.

Colossal quantities of high-quality vegetables that end up in the trash daily can be put to good use, merely if they are dehydrated and frozen.

For example, dried tomatoes, dehydrated onions, frozen green peas, and cut beans are in great demand. Hence, a huge domestic and export market for dehydrated and frozen vegetable exists.

The sole impeding factor for India to entering this lucrative market is the lack of adequate small scale manufacturing businesses that can provide such products.

Opening a unit that dried and frozen vegetables can open your doors to the large global market.

13. Indian bread (Chapati/ Paratha)

Almost every major city or industrial zone is witnessing an unchecked influx of single people- men and women. They converge on these cities, towns for employment.

Consequently, they are forced to live in accommodations that do not permit cooking or lack time and inclination to prepare their own meals.

Nowadays, another trend is for both spouses to work to earn extra income to meet rising inflation or for a better lifestyle. Chappatis, roti, and parathas are staples of the Indian diet, and most meals are incomplete without these types of bread.

A growing number of small scale manufacturers are now producing these Indian bread on an industrial basis and selling them in convenient packs at economical rates.

Machines to knead the dough and bake this bread are available at fairly reasonable prices.

14. Paper bags and envelopes manufacturing

Undoubtedly, recycling is fast gaining momentum. This is due to growing awareness of the need to preserve our environment.

You, too can help preserve the environment while making money by opening a small scale manufacturing business that makes paper bags and envelopes.

Since this is a manpower-intensive small scale business, you will also play a key role in providing employment. Generally, paper bags are made of discarded newspapers and similar materials.

These bags and envelopes are in high demand with large supermarkets, pharmacies, and other retailers. Especially since they cost less and impart a great impression of the retailer's being environmentally conscious.

The raw material you need is available aplenty, and equipment such as cutters is inexpensive.

15. Costume/ imitation jewelry manufacturing

Costume and imitation jewelry has never been out of fashion. In the past, it was the mainstay of the economically weaker segments of society.

However, as women, especially teenage girls, are becoming increasingly fashion-conscious, they look for matching accessories to suit their attire.

Online stores have also made fashion garments inexpensive. Correspondingly, India has a large but vastly untapped market for costume and imitation jewelry.

Women seek matching jewelry to go with their dresses. You can fulfill these needs by staying in touch with the latest fashion trends, often dictated by Bollywood movies.

Further, you can manufacture such costumes and imitation jewelry that are trending. Few can afford to buy jewelry made of precious metals such as platinum, gold, or silver for daily use.

Hence, you can meet the need by opening a small scale manufacturing business of costume and imitation jewelry.

16. Disposable plates, cups and crockery

Parties, celebrations, and picnics are round-the-year events. Nowadays, almost no host or organizer bothers to offer ceramic, melamine, or metal plates, cups, forks, and spoons to guests, invitees, or participants.

Instead, they rely upon food-grade plastic and Styrofoam plates and cups, forks, spoons, and knives for guests to relish their food.

Understandably, since they are inexpensive, lightweight, and disposable. Meaning it saves them the bother of washing. Paper plates and cups are also common nowadays.

Street-side food vendors also use paper plates and cups. Keeping in mind this heavy reliance upon disposable plates, cups, and plastic crockery, you too can open a small scale manufacturing business producing these products.

The market is huge and all parties get a slice of the pie.

17. Concrete blocks manufacturing business

Rest assured, India is witnessing a construction boom. This applies both- to civil construction, including residential buildings, to large infrastructural projects such as bridges and industrial units.

Especially in the building sector, the earlier trend of using traditional bricks is fast becoming extinct. Instead, these ubiquitous reddish-brown bricks are being fast replaced by concrete blocks of various types.

Understandably, with pressures to complete housing and other building projects faster, builders are constantly on the lookout for reliable suppliers of readymade concrete blocks.

Indeed, in some cases, the demand is so high that builders are willing to pay premiums to procure these concrete blocks.

Setting up a small scale manufacturing business of concrete blocks of various sizes is inexpensive while returns are assured and high.

18. Mangalore Tiles manufacturing business

Surprisingly, Mangalore Tiles, as they are called, are not made only in that coastal city of India’s southern state, Karnataka. They are now made in various parts of the Indian sub-continent as well as the Far East.

While those made in and around Mangalore are made of locally available clay, makers elsewhere use somewhat similar material.

Nowadays, Mangalore Tiles are used mainly to impart a decorative look to bungalows and buildings, thanks to their aesthetic appearance.

A huge export market for Mangalore Tiles from India also exists. Mangalore Tiles are made by small scale manufacturing businesses.

With some space and the required equipment, as well as proper raw materials, you can open a Mangalore Tile manufacturing unit. Making Mangalore Tiles nowadays has shifted from traditional processes used in the late 1800s to new, modern techniques.

19. Handbags, wallets and purses

Unmistakably, handbags, wallets, and purses form an essential part of our daily life. Regardless of whether you are female or male, you rarely leave your home without either of these.

Handbags, wallets, and purses can often cost a mini fortune. Especially those products made by designers or some highly reputed manufacturer.

However, a huge market exists for unbranded handbags, wallets, and purses. Almost everyone is tempted to buy a new one, provided the cost is commensurate with the quality.

A small scale manufacturing business that makes these essential items for women and men is something we recommend.

Provided you are setting up a unit in some area where you can easily access raw materials and procure the required manpower.

Here, skilled manpower is essential since people are always on the lookout for newer designs.

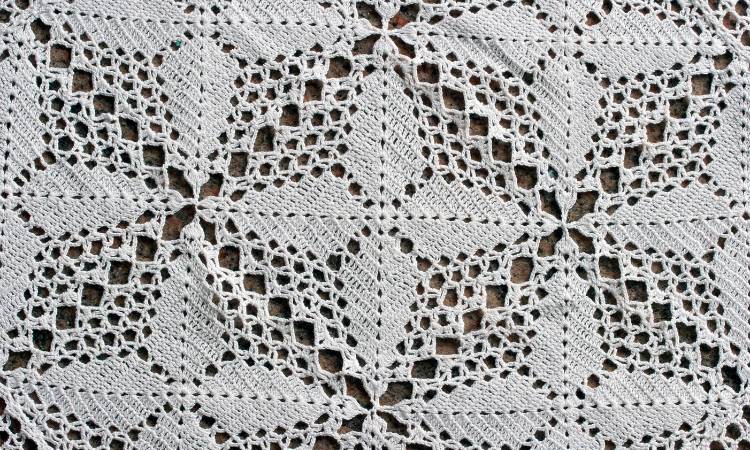

20. Bed sheet and blankets manufacturing

Several locations in India are known for manufacturing high-quality bed sheets and blankets. These include Solapur in Maharashtra and Davangere in Karnataka, to name a few.

However, these locations are known more for their tradition of manufacturing bed sheets and blankets. The demand for high-quality bed sheets and blankets, especially those made of cotton, continues to remain high.

Manufacturing these bedroom essentials is fairly easy provided you have skilled manpower and the required looms.

Setting up a small scale manufacturing business that produces bed sheets, blankets, and pillowcases is reasonably inexpensive. The market is huge and ever-growing.

21. Plastic tablecloth and tablemats

Increasingly, restaurants and households are dispensing with regular fabric tablecloths and tablemats. The reason is- washing and maintaining them is time-consuming and laborious.

Instead, they rely on disposable plastic sheets decorated with floral or other designs for use as tablecloths. Plastic tablemats are also in vogue since they allow easier cleaning- a mere wipe or wash in soapy water is sufficient.

Plastic tablecloths and tablemats are increasingly finding favor with restaurants too. This makes their manufacture a very lucrative business.

You can consider opening a small scale manufacturing business to produce these table accessories.

22. Vehicle accessories manufacturing

Here, we do not imply automobile spares. Instead, we suggest you open a small scale manufacturing business that makes stuff, including steering wheel covers, seat covers for cars and bikes, and other similar accessories.

India is a large market for used vehicles of all types. There is also a booming market for new automobiles. Further, Indians are also known to keep their vehicles generally excellent and attractive looking.

Cloth, artificial leather, and other such material are readily available, and so are skilled labor and machinery to manufacture these accessories on a small scale.

23. Spice powders manufacturing

Indian cuisine heavily relies on a diverse blend of spices. Admittedly there are giant players in the market. However, they have one inherent drawback.

Giant manufacturers do not take into consideration local or ethnic tastes. Instead, their spice powders are somewhat generic in nature.

Consequently, a small scale manufacturing business that makes spices suited to cuisines of certain or specific ethnicities will find a good market.

However, to enter into this business, you will require astute knowledge about the proportion of spices that will go into each powder.

You can decide upon the size of the package you plan to offer since stale spice powders lose their punch.

24. Medical requirements

Understandably, a huge market exists in India for medical requirements. These include surgical gloves, gauze, cotton swabs, and similar paraphernalia used at clinics and surgery rooms.

Generally, such material in India is provided by small scale manufacturing units. However, one of the requirements to open such a small scale manufacturing business is to require clearances from the Food and Drug Administration.

This certification is required to ensure that your product meets the prescribed standards and is safe for use at clinics and hospitals.

Interestingly, a lot of cotton products, including earbuds and cotton balls, are also used for cosmetic purposes. This expands the scope of your market.

You will also be able to bid in tenders floated by hospitals and the government to supply these products.

25. Aluminum and fiber-glass doors, windows

Nowadays, wood has become an expensive commodity. Furthermore, making wooden frames for windows is pricier.

Simultaneously, most people prefer fiberglass doors for bathrooms and toilets since they are water-resistant and have a longer life.

Additionally, they cost much lesser than their wooden variants. Fabricating aluminum frames for windows and making fiberglass doors of various sizes is a simple small scale manufacturing business to set up.

Once again, the machinery required is easy to procure, and the manufacturing unit does not require large premises. You can offer readymade solutions or take orders for tailor-made sizes.

A small export market for these items also exists, primarily in the Middle East and the Far East.

Financing your small scale unit

As we mentioned earlier, finances for a small scale manufacturing business can sometimes be challenging to find. However, you need not be discouraged.

The Micro Units Development and Refinance Agency (MUDRA), commonly called Mudra Bank, established by the Indian government, offers some assistance.

Mudra Bank is a scheme offered by the government through various banks. To avail of a Mudra Bank loan, you will require a comprehensive project report.

This must be submitted to any Public Sector Banks or other financial institutions participating in the Mudra scheme.